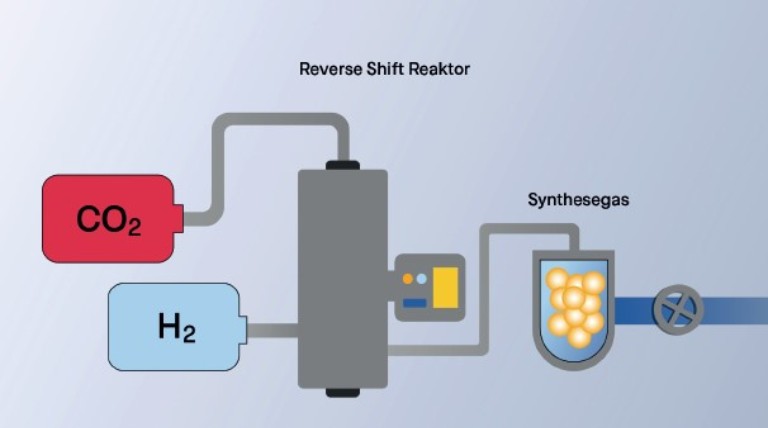

1. Gaseous carbon dioxide and hydrogen are piped into a reactor. Here, they are subjected to high temperatures and pressures to yield syngas, a mixture of carbon monoxide and hydrogen.

World’s largest power-to-liquid pioneer plant being built at Industriepark Höchst

Combining CO₂ and hydrogen to create valuable new resources for chemical production

Start-ups play an important role for Infraserv Höchst since they can trial and execute innovative sustainability projects using the infrastructure available at Industriepark Höchst . The industrial park thus serves as a platform for important innovations in the chemical and pharmaceutical industry. These projects are about more than just getting products market-ready quickly in order to turn a profit. They also engage in the kind of application research that will drive the industry forward in new and important ways for years to come.

Chemical industry is shaping a sustainable tomorrow today

Infraserv Höchst and the companies based at Industriepark Höchst have been modeling sustainability for years, developing strategies for CO₂-free chemical production and working to thoroughly defossilize industrial processes. We also develop sustainable efficiency enhancement programs to support worldwide efforts to mitigate climate change. There is no question that we in the chemical industry must do more to develop and promote sustainability in a larger international context in order to positively influence the overall system with regard to climate targets.

Attracting and collaborating with start-ups is a key element of our strategy. Industriepark Höchst supports the entire chemical industry value chain, from research to pilot plants to commercial-scale production. Start-ups play a critical role in this ecosystem because they can trial and execute innovative sustainability projects using the infrastructure that we have available.

Joachim Kreysing, Managing Director of Infraserv Höchst

Don’t emit CO₂ – recycle it!

That is why work is being done at Industriepark Höchst to stop climate change by drastically reducing CO₂ emissions. For example, are there ways to reintroduce CO₂ and other byproducts of chemical production back into the manufacturing cycle and thus achieve a circular economy? That is exactly what the ICO2CHEM joint project aims to do.

ICO2CHEM – aiming to “green” chemical production

Infraserv Höchst and the Provadis School have joined forces with partners from Finland, Italy and Germany in a European Union-funded project to answer one key question: Is it possible to industrially produce hydrocarbons from CO₂ generated in a biomethane upgrading plant that would otherwise escape into the atmosphere? The two precursor materials – which are abundantly available at the industrial estate – are fed into a pilot plant. The emissions-free Fischer-Tropsch process then converts these substances into non-petroleum-based mineral oils and waxes, which serve as precursors for making products such as paints, varnishes or solvents. A trial project succeeded in producing dozens of kilograms of these solid hydrocarbons. The entire synthesis process unfolds inside a microstructured Fischer-Tropsch reactor developed by our partner, INERATEC . The reactor yields hydrocarbons of varying lengths – some solid waxes, but liquid compounds as well.

This is thus an ideal process for manufacturing synthetic jet fuel – and a promising approach for gradually switching the aviation sector from conventional fossil fuel-based kerosene to a more ecofriendly fuel.

Fischer-Tropsch synthesis

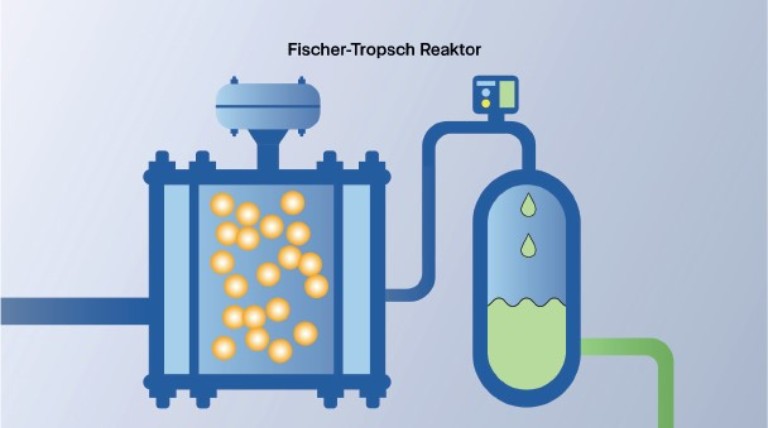

2. Water is separated out, and then the syngas is fed into a microstructured Fischer-Tropsch reactor developed by INERATEC , a Karlsruhe-based start-up. The gases react with a catalyst to produce hydrocarbons.

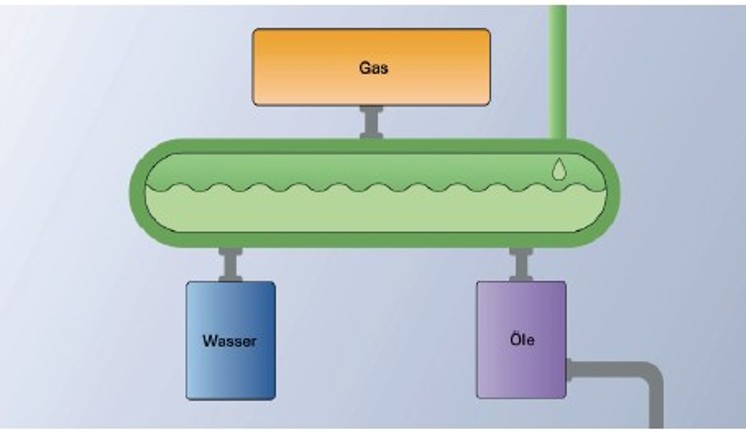

3. The reaction mixture flows into a container where water is again separated from the gas, oils and other hydrocarbons.

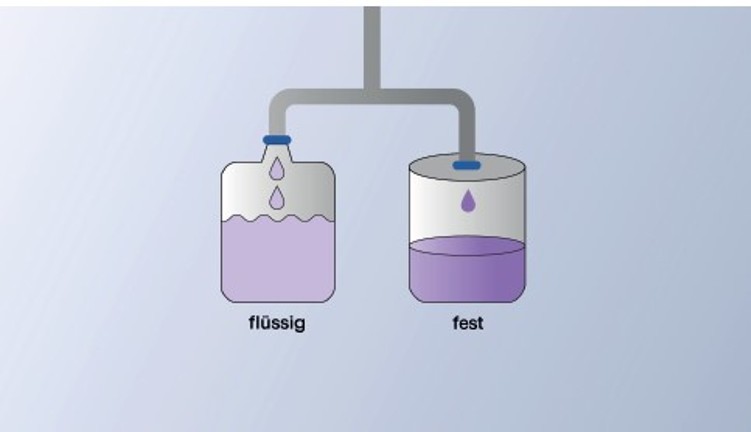

4. Hydrocarbons with different chain lengths can be produced at the end of the Fischer-Tropsch process: solid waxes and liquid oils.

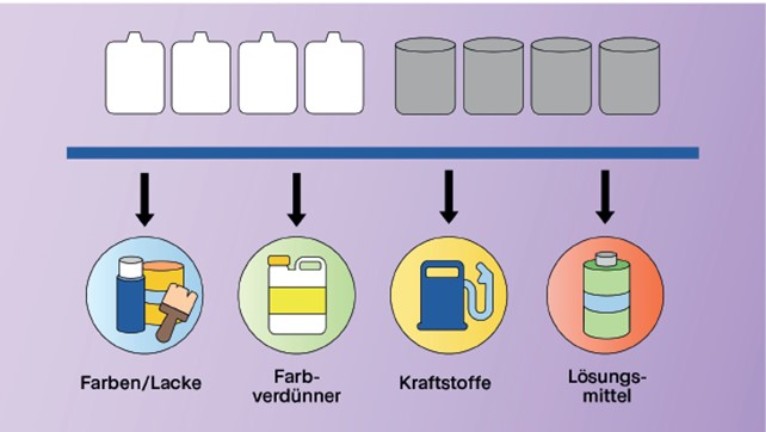

5. They can then be processed into paints, varnishes, thinners, solvents and synthetic fuels.

Synthetic jet fuel – a climate-friendly prospect for the future of aviation

After conducting successful experiments as part of the ICO2CHEM initiative, INERATEC revealed plans to build the world’s largest pioneer plant for the power-to-liquid production of synthetic fuels and e-chemicals at Industriepark Höchst. The facility should start manufacturing in 2024 and will produce around 4.6 million liters of synthetic fuel from up to 10,000 metric tons of biogenic CO₂ per year.

There is no way to electrify medium- or long-haul flights or ship transports in the foreseeable future. However, it is still possible to lower CO₂ emissions in this segment by using synthetic, carbon-neutral kerosene (i.e. aviation fuel) made from non-fossil resources via Fischer-Tropsch synthesis.

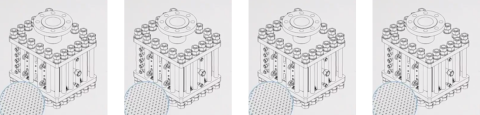

Synthetic kerosene is still being produced in very small amounts and is thus mixed in with conventional fuel extracted from fossil sources. Luckily, the output from the INERATEC pioneer plant can be readily scaled up to reflect increasing take-up of synthetic fuels by running multiple Fischer-Tropsch reactors in parallel.

Running Fischer-Tropsch reactors in parallel to manufacture large quantities of oils and waxes (image credit: INERATEC)

Technologies like power-to-gas and power-to-liquid play a pivotal role in the successful defossilization of our energy system.

Joachim Kreysing, Managing Director of Infraserv Höchst

Carbon-neutral aviation – ambitious project with extensive federal and state funding

The German federal government plans for the aviation sector to operate with two percent synthetic fuel by 2030, which it will mix in with conventional jet fuel obtained from fossil sources. To achieve this goal, the government is investing around two billion euros in power-to-liquid technologies.

Ideal conditions for pilot plants and start-ups

It’s not hard to see what attracts pilot plants and start-ups like INERATEC to Industriepark Höchst. The conditions are ideal:

- Infraserv Höchst provides suitable business space.

- Plants can be built quickly and expeditiously.

- Equipment can be integrated with Industriepark Höchst’s established infrastructure in a package that includes all the engineering and regulatory affairs management.

- Sufficient amounts of requisite fluids and precursors (CO₂, hydrogen and power) – all the supply lines are in place.

- Close proximity to chemical industry provides access to potential customers and raises your profile.

- Infraserv Höchst contributes its extensive experience as a service provider.

- Industriepark Höchst offers outstanding logistics links and close proximity to Frankfurt Airport.

The very first pilot plant revealed the tremendous potential that Fischer-Tropsch synthesis holds for manufacturing carbon-neutral materials. The challenge is to satisfy the chemical industry’s voracious energy needs with renewable resources and provide enough green hydrogen to keep the reactors running. It is more important than ever for our industry to tackle this challenge and develop solutions to it.

INERATEC’s pioneer plant marks the beginning of large-scale production of synthetic, carbon-neutral fuels in order to relentlessly chip away at the reliance on fossil-based raw materials. Obviously, synthetic fuel production is still dwarfed by the overall fuel needs of, say, the aviation industry, which uses around 10 million metric tons per year in Germany alone. However, it is a step in the right direction.

What matters is that Infraserv Höchst, in keeping with its self-image, is again working closely with partners on a technical solution. As chemical industry players, we believe that we are all needed to be part of the solution – and that makes promising pilot projects more important than ever before.